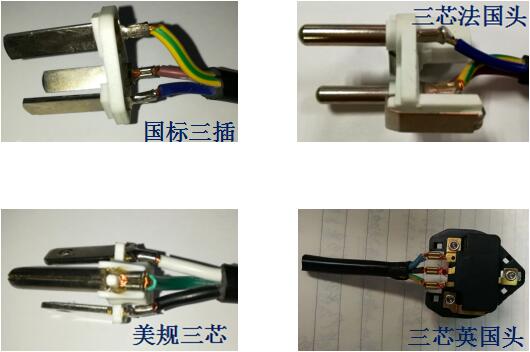

Automatic three core line integrated production line

It is suitable for French head, US rule three insert, GB three insert and so on.

Our brand will bring you more wealth.

- - Zhansheng Company is a professional manufacturer of intelligent automation equipment and integrated production line equipment for industrial 4.0 R&D, production, sales and service.

- - After years of equipment research and development and innovation, with fully independent intellectual property rights of the full set of automatic production equipment; has formed a complete set of intelligent integrated power plug line, widely used in the production of power plug line, instead of traditional processing. Through continuous optimization of its equipment, stable and efficient production, can really reduce labor, save space, reduce management costs, reduce process flow, for the sustainable development of enterprises to inject power.

Catalog

Chapter 1 project investigation...... Two

1, the introduction of...... Two

2, the current basic situation of customers and the status quo of integrated equipment...... Two

3, project function and data...... Three

[process flow comparison...... Three

[artificial contrast]...... Four

[labor and data]...... Five

[integrated equipment superiority]...... Six

[input cost accounting]...... Seven

[production area comparison...... Eight

The second chapter is the design criteria and basis... Nine

Safety and reliability...... Nine

The advancement...... Nine

Economy...... Nine

Benefit analysis... Nine

Investment efficiency...... Nine

Safety efficiency...... Nine

Personnel efficiency...... Nine

Production efficiency...... Nine

Management efficiency...... Nine

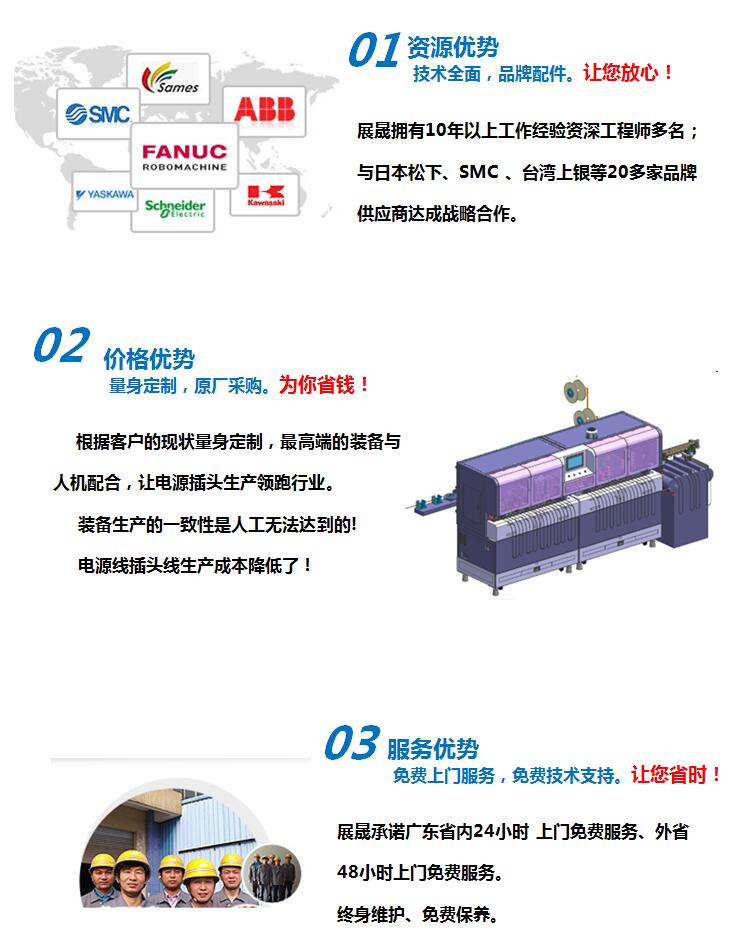

The third chapter is the 3 advantages of Chan Sheng... Ten

Thank you for reading... Eleven

Chapter 1 project investigation

one. Project introduction

[project name]: automatic three core wire integrated production line

[cooperation mode]: Manufacturer + customization (confidential within one year)

Processing capacity: about 1300 pieces per hour.

Saving labor: about 12 processes / people

[completion date] within 2 months from the date of signing the contract.

2. Project success cases

In 2015, Dongguan XXXX Company had a total output of more than 500, with an average monthly production capacity of about 1.2 million PCS products. In April 2015, we collaborated with our company to customize intelligent integrated equipment. In June of the same year, the first batch of intelligent integrated equipment was put into trial production line of Dongguan XXXX Co., Ltd. After nine months of verification, Dongguan XXXX Co., Ltd. The original number of more than 500 workers was reduced to 430, which saved about 2.6 million yuan in labor costs!

As of May 2017, Dongguan XXXX Co., Ltd. has ordered 15 sets of our equipment, including 6 sets of intelligent integrated equipment, the number of production has been reduced to 270, the monthly capacity of about 1.2 million PCS products remain unchanged, and Dongguan XXXX Co., Ltd. now occupies a quarter of the production area compared with 2015. Comprehensive estimation: Intelligent integrated equipment can reduce the cost of Dongguan XXXX Co., Ltd. by about 880,000 yuan per month.

Dongguan XXXX Co., Ltd. in line with the business philosophy of reducing labor, saving space, improving efficiency, to achieve: more orders, fast delivery, less labor, efficient and intelligent production mode

3, the current situation of customers and the status of integrated equipment

Traditional production line data (capacity: 23K/ class) / machine

|

Serial number |

Production process |

人工 |

|

1 |

out of |

1名 |

|

2 |

Line |

2名 |

|

3 |

strapping |

1名 |

|

4 |

loading, packing, marking |

1名 |

|

5 |

handling + storage |

2名 |

|

6 |

out of storage + handling |

2名 |

|

7 |

line |

2名 |

|

8 |

peel the outer part of the head, peel the core, and hit the head |

4名 |

|

9 |

tail stripping |

1名 |

|

10 |

molding |

1名 |

|

11 |

test |

1名 |

|

12 |

winding |

1名 |

|

13 |

QC |

1名 |

|

14 |

packaging |

1名 |

Integrated production data (capacity: 26K/2 class) machine

|

Serial |

production process manual |

人工 |

|

1 |

out of prison and |

1名 |

|

2 |

the outer part of the head is stripped and the core is stripped. |

1名 |

|

3 |

molding |

1名 |

|

4 |

test |

1名 |

|

5 |

winding |

1名 |

|

6 |

QC |

1名 |

|

7 |

boxing |

1名 |

[production difficulties]:

The staff has high proficiency in operation.

The quality of supervision is difficult for employees to operate arbitrarily.

Staff salaries are high, training costs are high, and profits are getting thinner and thinner.

Staff mobility, recruitment difficulties, short delivery time, resulting in customer orders can not deliver on time.

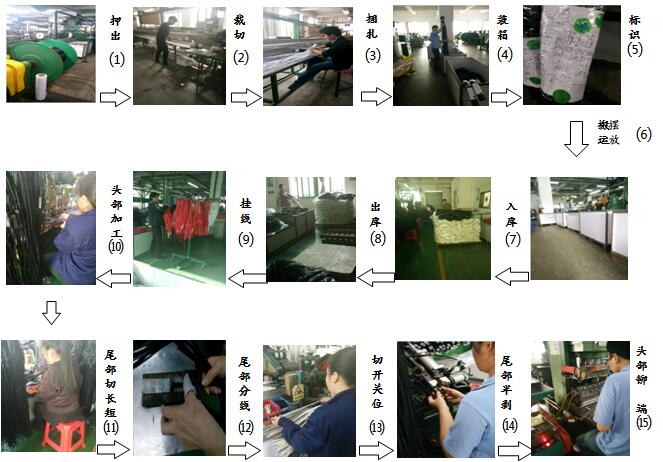

Traditional process:

Integrated production line process flow:

The integrated equipment is completed with only 5 stations.

Traditional production line data (capacity: 23K/ class) / machine

|

序号 |

production process manual |

人工 |

|

1 |

out of |

1名 |

|

2 |

Line |

2名 |

|

3 |

strapping |

1名 |

|

4 |

loading, packing, marking |

1名 |

|

5 |

handling + storage |

2名 |

|

6 |

out of storage + handling |

2名 |

|

7 |

line |

2名 |

|

8 |

peel the outer part of the head, peel the core, and hit the head |

4名 |

|

9 |

tail stripping |

1名 |

|

10 |

molding |

1名 |

|

11 |

test |

1名 |

|

12 |

winding |

1名 |

|

13 |

QC |

1名 |

|

14 |

packaging |

1名 |

|

15 |

total |

21名 |

|

Integrated equipment (capacity: 26K/2 class) machine |

|

序号 |

production process manual |

人工 |

|

1 |

out of prison and |

1名 |

|

2 |

the outer part of the head is stripped and the core is stripped. |

1名 |

|

3 |

molding |

1名 |

|

4 |

test |

1名 |

|

5 |

winding |

1名 |

|

6 |

QC |

1名 |

|

7 |

boxing |

1名 |

|

8 |

total |

7名 |

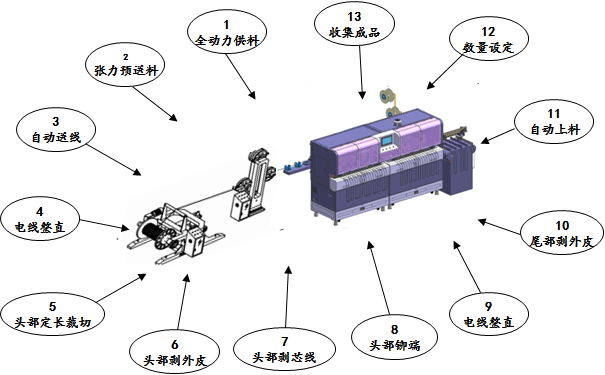

[host control system]

According to the current situation of the customer workshop environment, the intelligent production line for cable processing needs to adapt to AC 220V, 5-6 KGF clean and dry air power supply.

1, Japan Panasonic PLC controller;

2. Import Panaspnic servo motor in Japan

3. SMc pneumatic components in Japan

4. Work air pressure monitoring system;

5. Capacity record / reporting system;

6, alarm information system prompts.

[front / end processing]

When the front / end processing unit is put into the intelligent production line, it needs to be peeled outside and the core line is peeled.

The functions of riveting terminal and abnormal alarm system are as follows:

1, suitable for round wire three core power cable.

2. Digital control wire cutting length range: (200-10000 + 5MM)

3, mechanical adjustment of the length of outer skinning (range: riveting terminal 25~70mm, front and rear riveting terminals);

4. Digital control core stripping length (range: 5~30mm);

5, digitally control the position of riveting terminals.

6. Imported high speed steel peeling knives.

7. Adopt 4 ton riveting device, use OTP style mold, adjust pressure mechanically;

8. Cable positioning and handling system;

9. Terminal incoming abnormal monitoring system;

10, terminal rivet pressure anomaly detection system;

Integrated equipment advantages

Provincial Labor:

1. Each machine needs 1-2 people to cooperate to complete the process of pulling out, cutting, gluing, packing, packaging, material labeling, etc.

2. when the length of the cutting line is longer, 2 people are required to complete the work at the same time.

3., we must rely on manpower to pull into production lines or warehouses.

4. each line should be hanged manually on the wire frame specified in the production line to produce waste.

5. head processing requires 1 manual plus 1 semi-automatic stripping machines.

6. tail processing requires 1 manual plus 1 semi-automatic stripping machines.

7. wire rod outgoing library needs manual opening, placing order and manual forklift handling.

Provincial resources:

1. employees should reserve 20-50mm as a repeat processing loss when they line up.

2. each hand, each card board, each box, each by manual counting, easy to install more, less installed;

3. The shortage of material is easy to be caused by the inappropriate supply of cutting position, and the long backlog time of cutting wire is easy to be oxidized when the production schedule is tight.

4. the white line can easily lead to dirty wire after complicated process.

5. cardboard, box hanging line frame turnover difficulties;

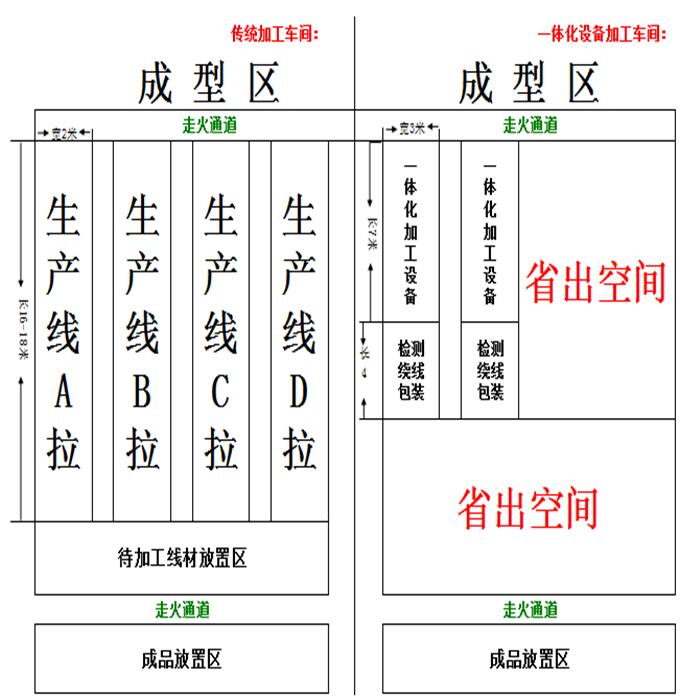

Provincial site:

1. the area of the card board is about 30% of the production line area.

2. the product specification and material number are large, and the card board occupies a large area.

3. when production is tight, inventory backlog needs to be increased.

4. boards and wooden boxes occupy 20% of the total plant area.

5; integrated equipment covers an area of 7 meters long * 2.5 meters wide * 2 meters high.

Input cost accounting

One, artificial

The value of the integrated equipment is embodied in 24 hours a day. It can produce value continuously. Two shifts are arranged daily. The annual value of the equipment is (21-7 people)* the average wage is 3500 yuan = 49000 yuan 2 = 24500 yuan.

Two, material loss savings

Save 20mm-50mm per wire. According to the length of finished wire = 1 meter, the daily production capacity is 24K * 26 days * 1.2 yuan * 0.02 = the average monthly savings of 14976 yuan.

Three, product advantage comparison

3.1 traditional processing:

Nissan can: 13000, use time: 10H, manual number: 21.

Number of traditional equipment: 7 sets

Traditional equipment value: 100000 yuan, the average wage per employee: 3500 yuan / month, 21 people pay 73500 yuan / month.

3.2 intelligent equipment processing:

Nissan can: 26000, use time: 20H, manual number: 7.

According to the calculation, it can save (21-7) people * 3500 yuan month = 49000 yuan, a equipment reference price of 420,000 yuan, machinery factory for customers to save 49,000 yuan month 14976 yuan month material 14,976 yuan month machine depreciation maintenance costs, about 8 months to recover the cost!

[safety and reliability]:

1, with microcomputer PLC control and servo motor control system.

2, monitor all links in an all-round way, and give an early warning to the anomalies that occur in the system.

3, strictly and according to the prescribed procedures automatically start and stop.

4. Choose reliable components.

[safety and reliability]:

1. Configuration software control technology is used instead of VC programming technology, which not only improves the reliability but also makes the program more universal.

2, the use of infrared identification system, high precision identification cable riveting accuracy.

[Economy]:

Because the system is designed according to the principle of unattended, so the site does not need personnel on duty, thus saving a lot of human resources.

[investment returns]:

Save the repeated investment cost and maintenance cost of processing (cutting machine, peeling machine, terminal machine and other equipment);

The cost of material handling, quality supervision, personnel management and so on should be saved.

Develop cable intelligent processing line, invest once and benefit for a long time.

[safety benefits]:

The intelligent production line reduces the possibility of casualty caused by personnel fault.

Improve working environment, improve safety factor and ensure personal safety of workers;

[personnel benefits]:

Achieve unmanned operation and regular inspection, effectively reduce personnel costs;

Achieve intelligent control, reduce labor intensity;

Reduce post employment and improve staff efficiency;

[production efficiency]:

Reducing manual operation errors and prolonging the service life of equipment;

Improve the ability to analyze and judge the failure of equipment, and reduce the downtime accident.

[management effectiveness]:

It provides a high-speed, safe and reliable operation platform for intelligent manufacturing.

We have 3 advantages for you to customize the most cost-effective wire and cable processing equipment.